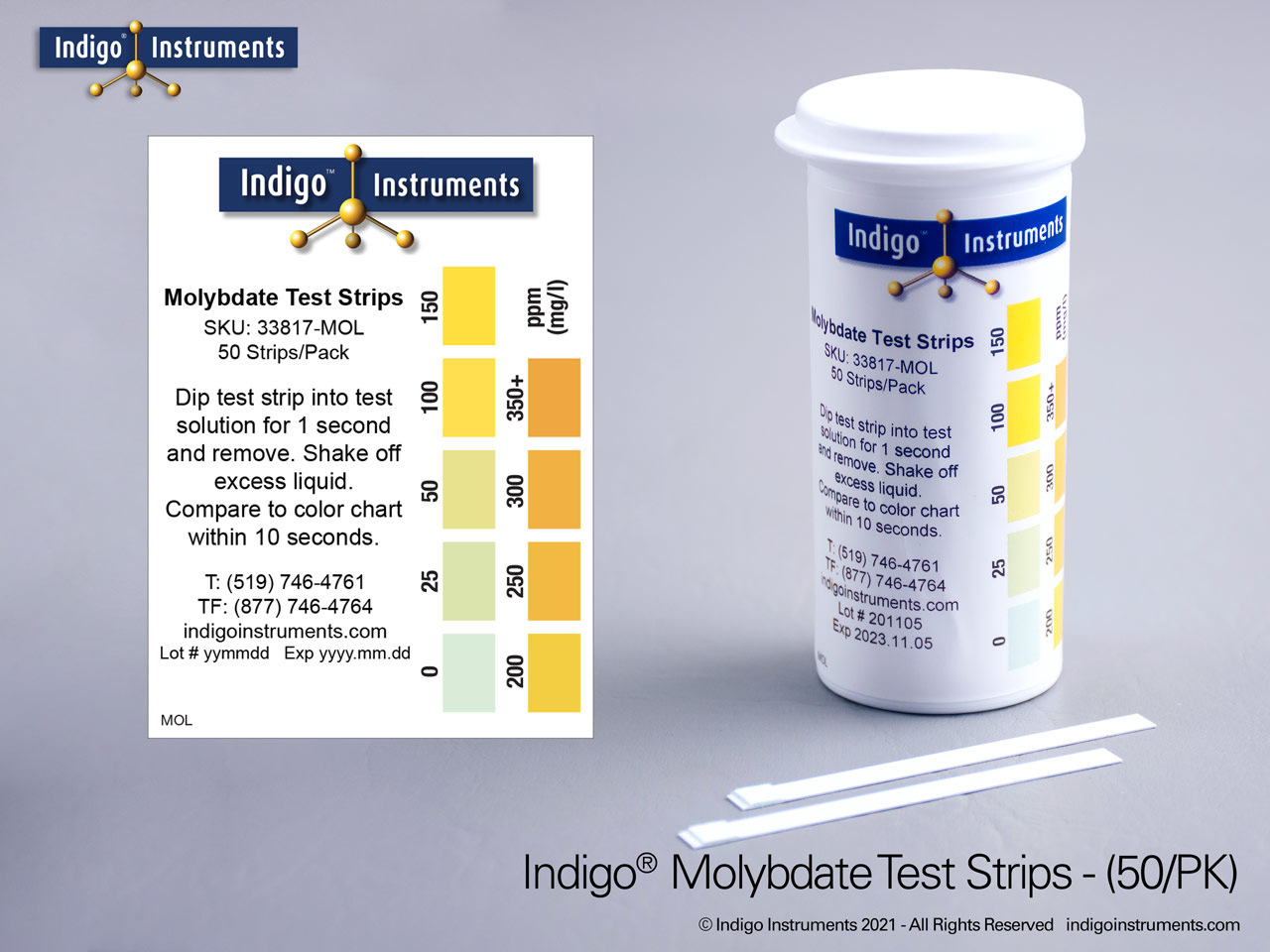

Molybdate Corrosion Inhibitor Test Strips

SKU: 33817-MOL

Measure molybdate levels up to 350 ppm in boiler and condensate systems with fast, accurate Indigo® Molybdate Test Strips. Verify corrosion inhibitor balance quickly without waiting for lab results.

Molybdate-based inhibitors are widely used in industrial and institutional boiler systems to prevent corrosion and scaling in high-temperature environments. Regular monitoring ensures that inhibitor concentrations remain within optimal ranges, typically 150-300 ppm, to form stable, protective films on metal surfaces. Indigo®'s 0-350 ppm molybdate test strips deliver reliable, on-site measurements in seconds, giving plant operators immediate control over treatment dosing and blowdown schedules.