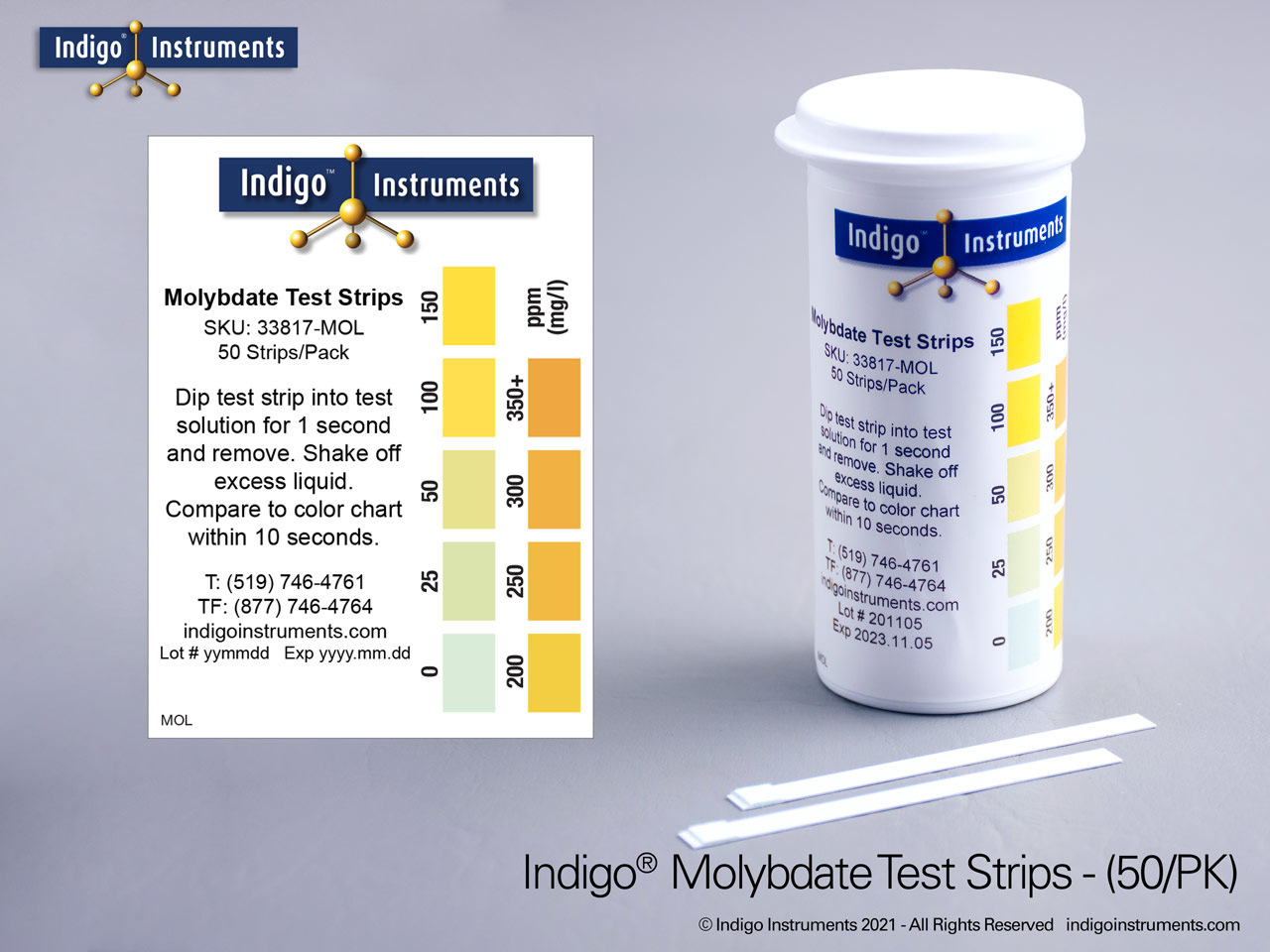

Boiler Corrosion Inhibitor Control Test Strips

SKU: 33817-MOL

Monitor molybdate corrosion inhibitors in closed-loop cooling and HVAC systems. Verify protective levels quickly with 0-350 ppm Indigo® molybdate test strips.

Closed-loop cooling and HVAC systems rely on corrosion inhibitors such as molybdate to protect metal surfaces from oxidation and pitting. Regular testing ensures that treatment levels remain within target ranges to prevent corrosion while minimizing chemical use. Indigo®’s molybdate test strips provide a quick, on-site indication of inhibitor concentration, helping facility engineers maintain efficient, low-maintenance systems without lab delays.