Disinfectants (Sanitizers)

Buy Indigo® test strips, the brand you can trust for accuracy & technical support. Just click on a subcategory below to see the complete list. Great unit prices with up to 15% off on quantity and delivered costs that beat "free" shipping".

Choose from 21 Indigo® test strips for your specific disinfection & sanitizing needs. All come with 100 test strips/vial and a minimum guaranteed 3 year shelf life. We provide full documentation provided on-line for every type of Indigo® sanitizer/disinfectant test strips including Certificates of Analysis & Stability & SDS Statements; Certificates of Conformance available on request. Optional next day delivery in any quantity of most items.

Need help? Call us toll free at (877)-746-746-4764 for immediate assistance. Or e-mail your questions with 1 hour response typical during business hours, M-F, slightly longer on weekends. Still not convinced? Click on Description to read more.

Indigo® Disinfectant & Sanitizer Test Strips

We're a small business that's been on-line since 1994. We've been selling top-of-line, US made test strips since 2007 (Wayback formatting is a bit off).

What our Customers Say

(Real Reviews-Not AI Generated Fakes; Click on the name to view the source at Google.)

Roberta Vigil: Indigo Instruments defines the purpose for the test strips and places them in easy to recognize categories. They are also clear about what type/state of chlorine the strips test, which most sellers don’t make clear. The BONUS is the qty of strips in each vial (100 vs the typical 50), fast and consistently accurate all for a price that beats other sellers!

Ronald Rosenberg: I purchased Indigo Chlorine Test Strips 0-300ppm. The sales person I spoke with was excellent and I received the items exactly when she said I would. Best of all the product was excellent. There was a clear delineation of the colors on the test strip so you could differentiate the different ppm. I would definitely repurchase this item.

Preston West: Prices are very reasonable. I love the selection of educational products. I actually came to this website for practical purposes... It's so nice to have niche things like this outside of Amazon.

Helen Kees The quick and prompt service on my 0 to 10 ppm chlorine test strips is much appreciated. I loved the quality at a cost less than Amazon. But the real deal that drove me to leave a review was that I called back a week or so after receiving the product and asked for spec sheets requested by my organic inspector. I was treated like I had spent a million bucks and the info was at my fingertips within a minute. This kind of service is invaluable.

GoFloat Penticton: We have used hydrogen peroxide test strips from Indigo Instruments for years and they have been extremely dependable. The price is unbeatable, ordering is super simple and the product arrives quickly. Indigo Instruments went out of their way to confirm the test strips are adequate for use within our unique industry and were absolutely amazing to work with.... Thank you Indigo Instruments for being amazing. You've earned my business for life!

Chemically Curious?

Indigo® test strips for chemical sanitizers & disinfectants are an essential tool in the control of infectious microorganisms. They are approved for food & non-food contact surfaces such as handrails, dishes & cutlery in restaurants, hospitals, daycare, cruise ships and much more. Whether you need residual level sensitivity or high level for more robust applications, we have what you need.

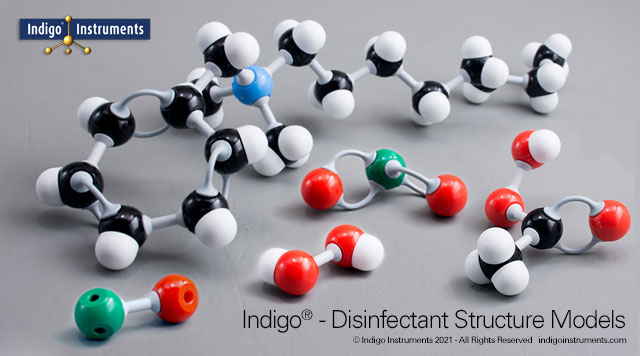

Counterclockwise, from top: benzalkonium; hypochlorite; hydrogen peroxide; chlorine dioxide; peracetic acid.

Indigo® sanitizer & disinfectant test strips are available in all ranges needed to confirm the correct dilution of typical commercially available disinfectant chemicals.

- Chlorine & Iodine: 6 ranges for chlorine, 1 iodine

- Chlorine Dioxide: 2 ranges

- Hydrogen Peroxide: 4 ranges

- Peracetic Acid: 4 ranges

- Quaternary Ammonium Chloride: 4 ranges

All come with a minimum guaranteed 3 year expiration so stock up & save. No one beats our 10+ price delivered to your door.

Sanitization vs Disinfection

These terms are often used interchangeably but in practice they are different. Disinfectants usually have greater efficacy against pathogens while most sanitizers target bacteria that cause foodborne illness. Disinfectants generally have broader killing capability to meet the needs of healthcare and education settings.

Sanitizers will reduce the number of Staphylococcus aureus and either Klebsiella pneumoniae or Enterobacter aerogenes bacteria by a factor of 10-3 or 99.9% but does not eliminate them. This is considered adequate for surfaces such as dishes, utensils, cutting boards, high chair trays as well as pacifiers & toys that children might put in their mouths.

Disinfectant chemicals can often be the same as sanitizers but are used at higher strength to ensure they will kill or inactivate bacteria, fungi and viruses or require a much longer exposure time. Using the Environmental Protection Agency's (EPA) definition, they can be a “substance, or mixture of substances, that destroys or irreversibly inactivates bacteria, fungi and viruses, but not necessarily their spores"

This greater effectiveness is desired for hard surfaces where the chance of transmitting the germ to others is likely. This can include diaper change tables, counter tops, door & cabinet handles, and toilets and other bathroom surfaces. Ideally, the disinfectant will leave an antimicrobial film that will have a longer term residual effect.

Disinfectants should be odorless or have a pleasant odor and be economical to use routinely. This generally means they are available as concentrates that can be diluted in water and are stable for extended periods.